Water Treatment Methods

There are a number of water treatment methods on the market that control Legionella, Pseudomonas and other waterborne pathogens.

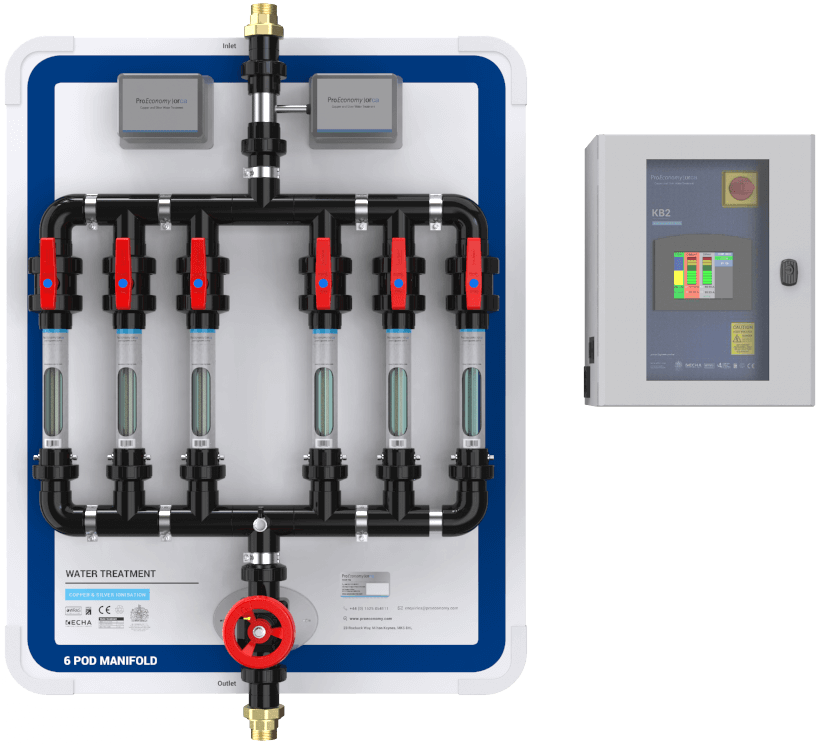

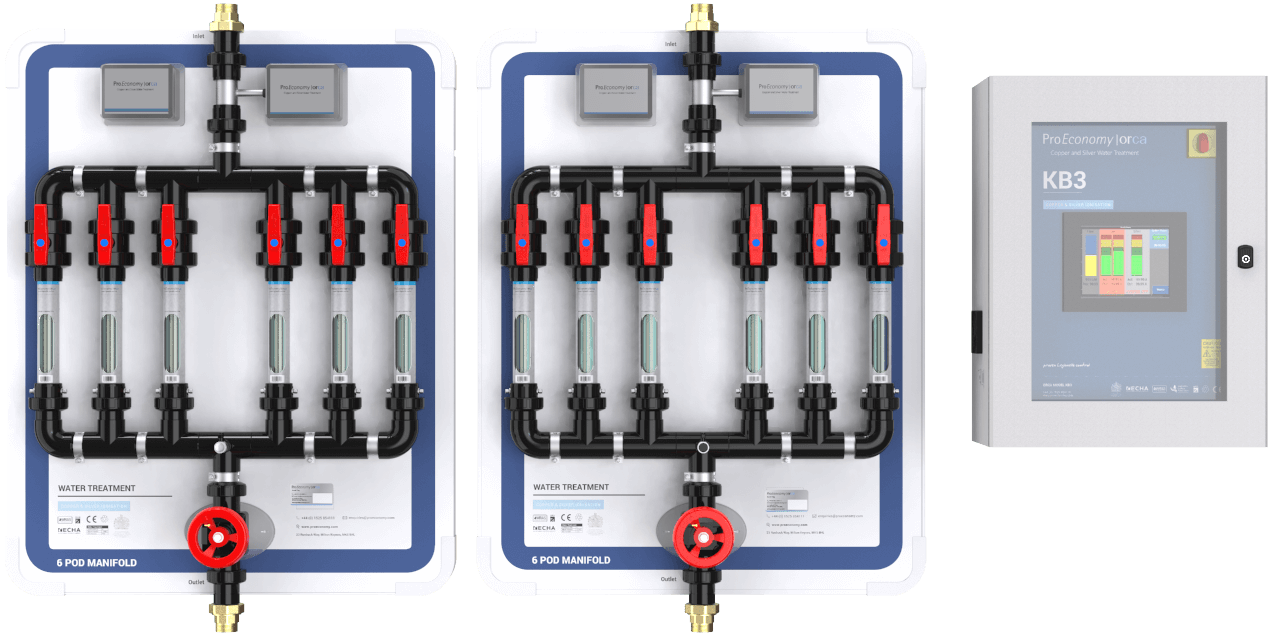

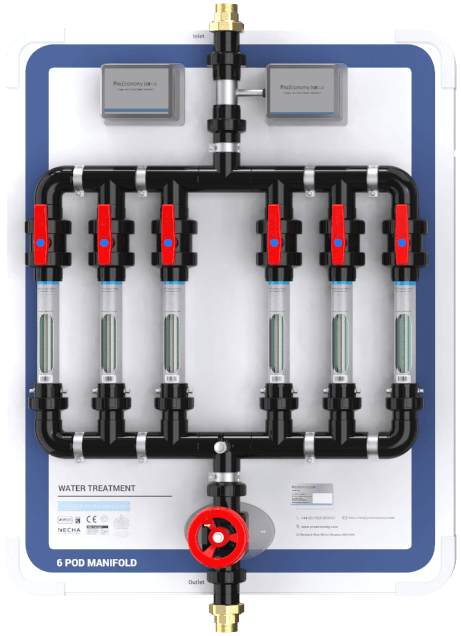

The most commonly used measures for Legionella control are intermittent heat and flush, temperature control, chlorine dioxide and copper silver ionisation. ProEconomy's Orca copper silver ionisation system offers 100% Legionella control, no COSHH issues and is compliant with HTM 04-01.

Standardized Evaluation Criteria for Disinfection Methods

A 4-Step Approach (Adapted from Stout and Yu, 2003)

- Step 1

Demonstrated efficacy in vitro against Legionella.

- Step 2

Reports of anecdotal experience of efficacy in controlling Legionella contamination in individual hospitals.

- Step 3

Peer-reviewed and published reports of controlled studies of prolonged duration of efficacy in controlling Legionella growth and preventing cases of hospital-acquired Legionnaires’ disease in individual hospitals.

- Step 4

Confirmatory reports from multiple hospitals with prolonged duration of follow-up (validation step).

Chemical Water Treatment Methods

There are many popular methods of chemical water treatment on the market, including:

- Chlorine dioxide

- Oxidising Chemicals

- Intermittent shock injection of chlorine

- Copper Silver Ionisation

Although a popular method of Legionella control, chemical water treatment can cause health hazards to humans and the environment. Unlike other chemical water treatment methods, copper silver ionisation has no COSHH issues and is safe to use.

You can find out more about the different chemical water treatment methods below. Alternatively, contact our team if you have any questions.

Temperature Control

Temperature control has been the method traditionally applied to control Legionella in water systems. It entails having to obtain 55°C and above after running any hot water tap for 1 minute, and 20°C and below after running any cold water tap for 2 minutes (DH HTM04-01 2016).

Unfortunately, pathogens in biofilms are protected as penetration by temperature is limited. This may cause pieces of the top layers of biofilm to break loose under the action of shear forces from the water. These can then settle elsewhere in the water system (Center for Biofilm Engineering). Furthermore, mixing valves are often used to avoid the risk of scalding. These valves will mix the water to a temperature at which pathogens grow most rapidly, and their inner components often include materials that encourage biofilm formation (DH HTM04-01, 2016).

In fact, only 13% of the results of tests carried out by the UK Building Services Research and Information Association (BSRIA) in 1996 using temperature control were free of Legionella.

Ultra Violet light (UV) and Ozone (O3)

Ultra Violet light (UV) and Ozone (O3), according to HSE HSG274 and HTM04-01, are not intended to be dispersive. Instead, they are designed to have their effect only at or very close to the point of application. Therefore, removing biofilm in water systems is difficult, if not impossible.