Water treatment for dialysis units must be chemically safe, have no COSHH issues and be compliant in order to safely control Legionella and other water borne pathogens in dialysis fluid. In this blog we take a look at dialysis water treatment and how our Orca copper silver ioinsation system can successfully control Legionella and prevent the contamination of dialysis units.

About Water Treatment For Dialysis Units

Approximately 400 litres of water are used per week for producing dialysis fluid. Therefore, it is important to monitor the chemical and microbiological purity of this water with water treatment for dialysis units (Pontoriero et al 2003). Hospital dialysis units have to deliver high purity water which is free from contaminants. Therefore, metals and chemical compounds should be removed from it. To ensure the water is free from impurities standard drinking water undergoes additional treatments such as filtration and reverse osmosis.

What Can Contaminate Dialysis Units?

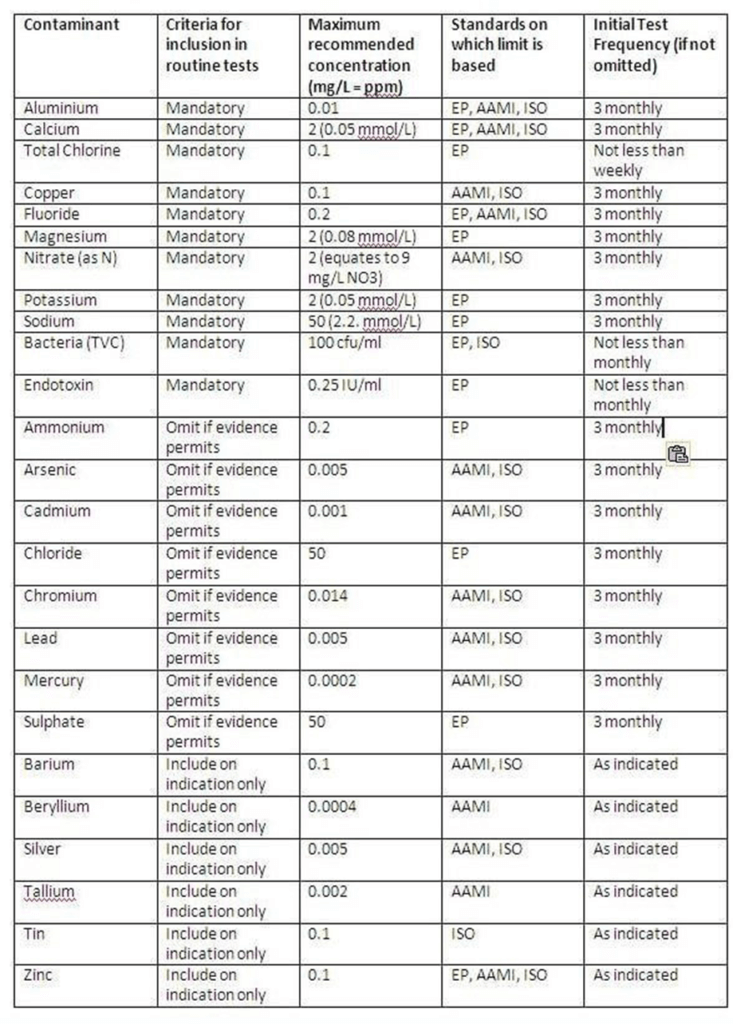

Water used for the preparation of dialysis fluid should at least meet the minimum standard of purity in Table 1 (Mactier 2007).

Table 1

Table 1 is from the Renal Association’s document “Clinical Practice Guidelines Module 2: Haemodialysis”. It shows the list of possible contaminants and their maximum recommended concentration in water for dialysis.

As shown in the table, contaminants include the chemical elements that are widely used in products and processes and thus can end up in water courses (e.g. aluminium, calcium, potassium, sodium, magnesium, chlorine, chloride, fluorine, fluoride, copper, cadmium, lead, mercury, silver, tin, zinc); chemical compounds (e.g. nitrate, ammonium, sulphate) as well as bacterial contaminants (e.g. bacteria, TVCs and endotoxins).

Removal of these contaminants from water has to be carried out to ensure that maximum concentrations of chemical and microbial contaminants allowed in dialysis water are not exceeded. This is usually done by filtration. If the filtration equipment fails then contamination of the dialysis water and the patient’s blood could occur.

These contaminants can be omitted from routine tests if data is available to show that the levels in the water supplied to the unit rarely exceed the limit in the table. This data should be obtained from the municipal water supplier or from tests on the raw water if it is obtained from a private source (Mactier 2007).

Table 1: Maximum recommended concentrations for chemical and microbial contaminants in water for dialysis:

Note: Antimony (AAMI limit 0.006 mg/L) and selenium (AAMI and ISO limit 0.09 mg/L) have been excluded from this table as the limit for drinking water in the UK is lower than the limit for water for dialysis.

Legionella in Water Systems

Legionella is a disease-causing microorganism, which is ubiquitous in water systems. The microorganism can survive extreme water temperature ranges, 0°C to 63°C (Nguyen et al. 1991), with an optimum temperature growth range between 38°C and 46°C. The bacteria multiples rapidly in untreated or ineffectively treated water systems.

L. pneumophila is well known for causing Legionellosis (Legionnaire’s disease and Pontiac fever). It is particularly dangerous for hospital patients that have a compromised immune system.

Therefore, Legionella has to be controlled in water systems, especially in hospitals. Many control strategies exist, but, the Legionella control system cannot interfere with or contaminate the dialysis system.

Which Legionella control method is less likely to contaminate Dialysis water units?

The dialysis filtration system can fail if using compounds like silver hydrogen peroxide as a biocide to control Legionella in the water system. This happened in Leicester General Hospital some years ago (Martin 2008). The filtration system was not able to cope with the high concentration of silver hydrogen peroxide in the water. Sadly this resulted in contamination of the dialysis water.

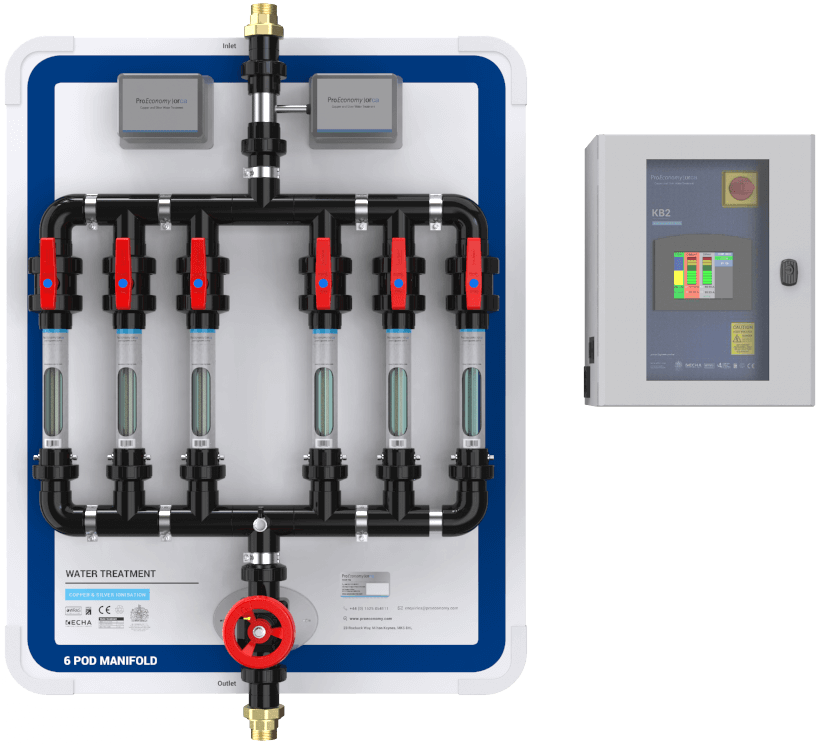

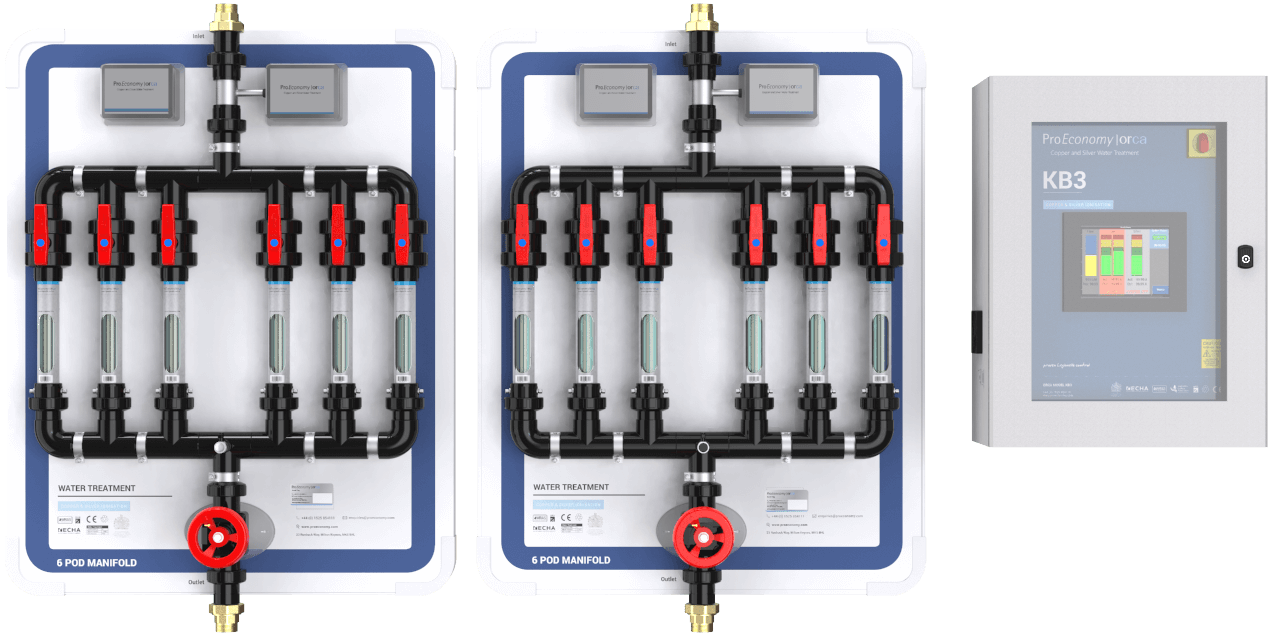

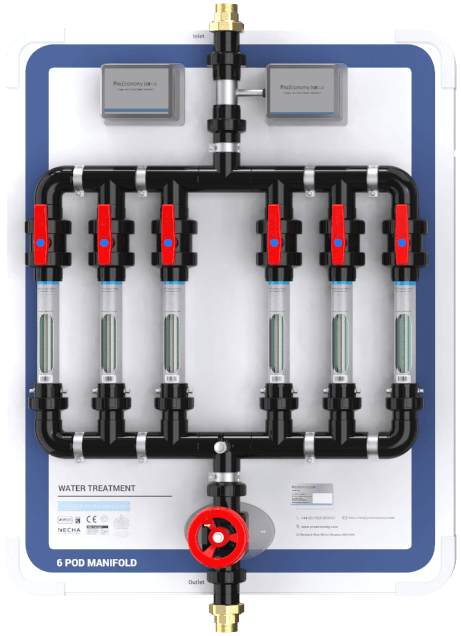

This would not have happened if the hospital was using pure Copper Silver Ionisation for pathogens control in the water systems. Instead, the dialysis water filtration system would have been able to cope without any problems. This is because the levels of ions of copper and silver released into the water by the water treatment system are extremely small (0.200-0.800 mg/L for copper and 0.020-0.080 mg/L for silver).

The Orca Case Studies

ProEconomy, the only providers of the Orca copper and silver ionisation system for pathogens control in water, have carried out analysis to measure levels of copper and silver before and after dialysis water filtration. The results, in Table 2, show that the copper concentration before the RO unit was 0.246 mg/L and after the unit was <0.003 mg/L. This demonstrates almost complete removal to well below the recommended levels (0.1 mg/L). The silver concentration before the unit was 0.059 mg/L and after it was 0.0004 mg/L. Again, this shows almost complete removal to well below the allowed levels (0.005 mg/L).

Table 2: Copper and Silver Before and After Dialysis Water Filtration:

| Sample Id | Copper (mg/L) | Silver (mg/L) |

| Maximum recommended concentration (Renal Association, AAMI-ISO) | 0.1 | 0.005 |

| Renal Dialysis Before osmosis | 0.246 | 0.0593 |

| Renal Dialysis After osmosis | <0.003 | 0.0004 |

It is vital that water treatment for dialysis units control Legionella and do not interfere with the safe functioning of the dialysis system. The Orca copper silver ionisation system has been proven to control Legionella, Pseudomonas and other water borne pathogens in dialysis units whilst maintaining optimum safety and compliance.

To find out more, contact our team.