What Are Biofilms?

Biofilms are layers of microbial cells that become attached to surfaces submerged in water. Legionella is one of the important bacteria species that contaminate water systems from public water supplies and borehole waters. They then colonize these systems from biofilms, where they are protected from disinfection. In fact, biofilms play an important role in the spread of Legionella. This is because they provide nutrients for their growth as well as a protective environment, enabling them to survive water treatment processes (Lin et al 1998; Kuiper et al 2004). Biofilms also harbor other pathogenic bacteria, such as Pseudomonas spp. and Acinetobacter baumannii.

Where Do Biofilms Form?

Areas of low water flow and where water is stagnates are where biofilms are Tlikely to form. Not surprisingly, biofilms are found in anthropogenic water systems in deadend pipes that are closed at one end through which no water passes. They are also found in deadleg pipes, through which water only passes when there is draw-off from the fitting. Complicated tap/mixer taps fittings are also ideal places for biofilms to form. Often, I come across new taps and tap fittings with complicated designs aimed at solving the problem of pathogen contamination. However, I think rather than solving the problem, due to the addition of many nooks and crannies, these fittings might actually add to the problem by providing an ideal environment for biofilms build up. Preventing Legionella and Pseudomonas contamination of these systems is, therefore, a difficult technological challenge.

Although the efficacy of a biocide is best measured in the environment, we also measure it by using a laboratory method where biofilm is grown under fluid flow conditions similar to the environment where the biocide will be applied. Below are summary descriptions of two studies showing the effectiveness of copper and silver ionisation for controlling biofilms, Pseudomonas spp. and Acinetobacter baumannii associated with biofilms.

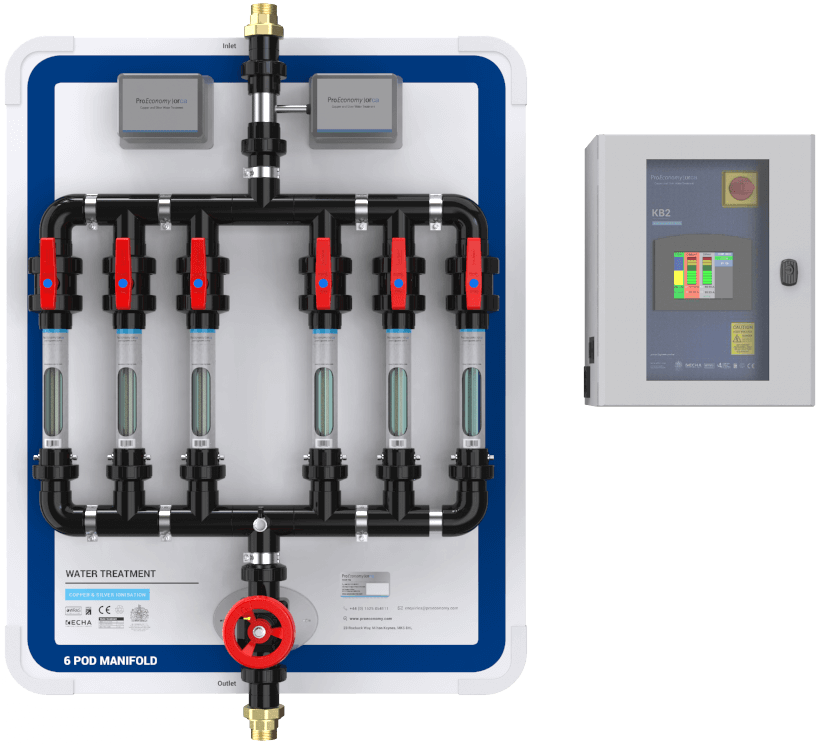

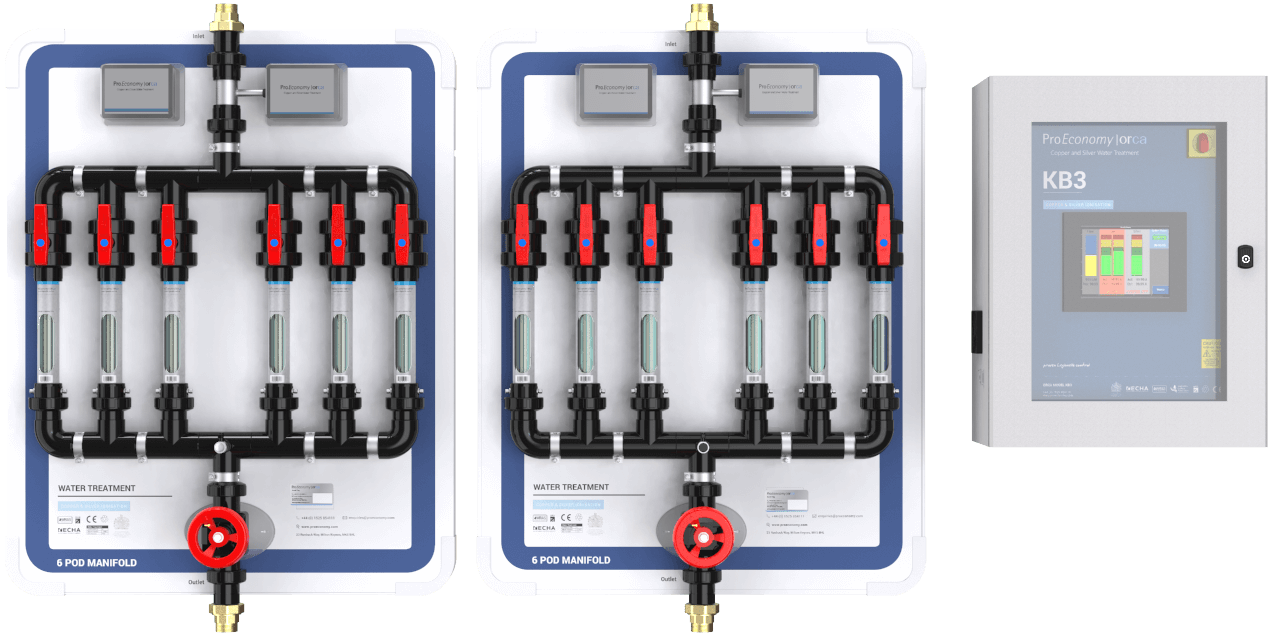

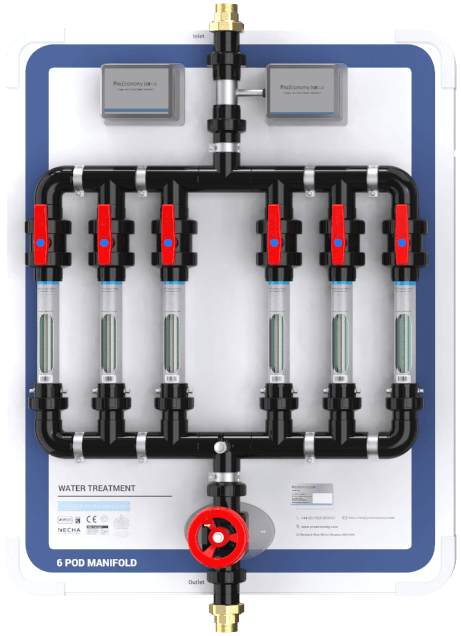

Controlling Biofilms With Copper Silver Ionisation

A BSRIA project (BSRIA TN6/96) demonstrates how we can control biofilms in a rig by using copper and silver ionisation. Biofilms were analysed in the copper pipework circuits and the glass reinforced plastic (GRP) tanks. This was done by removing small copper coupons from the copper pipework circuits and GRP coupons from the tanks. These coupons were covered with biofilms and disinfected by copper-silver ionisation. Overall, the cistern GRP and cold water circuit copper coupon samples of the rig that was supplied with hard water demonstrated a 30% drop in biofilm coverage on commencement of disinfection.

After 14 days of disinfection, the percentage coverage on the surface of the hot water circuit copper coupon was reduced to less than 5%. The percentage coverage on the cistern GRP coupon sample began, however, to increase again to 30% after 21 days. The authors suggested that biofouling returned on the cistern GRP coupon because it was difficult to maintain silver concentrations above 0.01mg/L due to scaling of the silver electrodes, which obstructed the release and presence of silver.

I found in my own study that scaling can be successfully removed by switching the electrodes polarity. Copper and silver ionisation disinfection resulted in a rapid decrease in biofilm coverage on the cold water copper coupon samples of the rig that was supplied with softened water, from over 50% to less than 5%. A more gradual constant decrease was noted, to less than 10%, on the cistern GRP and the hot water copper coupons. The study showed that where operated at concentrations of 0.4mg/L copper and 0.04mg/L silver, copper-silver ionisation was effective for controlling biofilms.

Shih and Lin Study On Controlling Biofilms

Shih and Lin (2010) also demonstrated that copper and silver ionisation was effective in controlling biofilms. A model plumbing system, consisting of four transparent PVC biofilm sampling pipes, was designed. A 14-day inoculation period was followed by 120-hours disinfection. The inoculum solution consisted of a bacterial suspension (3 x 106cfu/ml) comprising environmental isolates of Pseudomonas aeruginosa, S. maltophilia, and Acinetobacter baumannii,. Copper and silver concentrations were maintained at 0.2mg/L copper and 0.02mg/L silver to 0.8mg/L copper and 0.08mg/L silver. Furthermore, complete inactivation of the biofilm-associated P. aeruginosa was achieved within the first 24 hours. Biofilm-associated S. maltophilia was completely inactivated in 48 hours, and 99.9% of biofilm-associated A. baumannii was killed in 12 hours.

References

Building Services Research and Information Services (BSRIA 1996). Application Guide AG 2/93. Water treatment for building services systems. Building Services Research and Information Services (BSRIA) Technical Notes TN6/96. Ionisation water treatment for hot and cold water services.

Kuiper M.W., Wullings B.A., Akkermans A.D.L., Beumer R.R., van der Kooij D. (2004). Intracellular proliferation of Legionella pneumophila in Hartmannella vermiformis in aquatic biofilms grown on plastized polyvinyl chloride. Applied and Environmental Microbiology. 2004 70:6826-6833.

Lin YE, Stout JE, Yu VL, Vidic RD. (1998). Disinfection of Water Distribution Systems for Legionella. Seminars in Respiratory Infections 3:147-159.

Shih, H.Y., Lin, Y.E. (2010) Efficacy of copper-silver ionisation in controlling biofilm and plankton associated waterborne pathogens. Applied and Environmental Microbiology 76:2032-2035.